Product Center

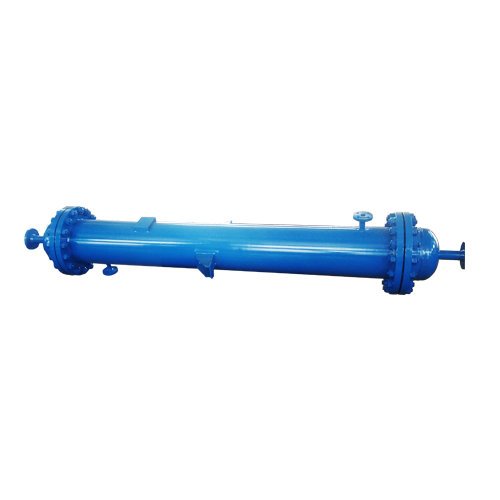

Your Current Location:Home > Product CenterA kind of shell-and-tube heat exchanger, which belongs to petrochemical equipment, consists of main parts such as tube box, shell and tube bundle. It is named after its heat exchange tube is U-shaped. The U-shaped tube heat exchanger has only one tube plate, and both ends of the tube are fixed on the same tube plate. The characteristic of this type of heat exchanger is that the tube bundle can be expanded and contracted freely, no thermal stress will be generated due to the temperature difference between the tube and the shell, and the heat compensation performance is good; the tube pass is a double pass, the process is longer, the flow rate is higher, and the heat transfer performance is better. ; Strong pressure-bearing capacity; the tube bundle can be drawn out from the shell, which is convenient for maintenance and cleaning, and has a simple structure and low cost.

The spiral tube heat exchanger is made of one or more sets of spirally wound tubes placed in the shell. It is characterized by compact structure, larger heat transfer area than straight pipes, and smaller temperature difference stress, but it is difficult to clean inside the pipe and can be used for heating or cooling fluids with higher viscosity.

The bellows heat exchanger is based on the traditional tube-and-tube heat exchanger, applying the theory of enhanced heat transfer and the unique design of the peaks and troughs of the heat exchange tube, which makes a major breakthrough in the performance of the heat exchanger.

The corrugated tube is a double-sided enhanced heat transfer tube that is processed by a special process on the basis of an ordinary heat exchange tube and has concave and convex waves inside and outside the tube, which can strengthen the inside and outside of the tube. From the waveform, it is divided into two categories: spiral corrugation and annular corrugation. Because the joints of spiral corrugated pipes are difficult to handle and their use is limited, ring corrugated pipes are now widely used. Ring bellows are divided into trough-shaped bellows, trapezoidal bellows, zoom tubes, and corrugated tubes.

Copper has good corrosion resistance and thermal conductivity, and copper heat exchange tubes have good heat transfer coefficients.

Zhengwei heat exchanger can customize heat exchangers of different materials, such as copper, aluminum, titanium, nickel, etc. according to customer requirements.

Weihai Zhengwei Machinery Co., Ltd. is a high-tech enterprise integrating complete independent research and development, manufacturing, and marketing systems. It can provide special customized design and manufacturing according to the volume, working temperature, and working pressure provided by customers.

Production of various volume gas storage tanks, chemical storage tanks, and petroleum storage tanks

The material can be made of stainless steel, carbon steel, non-ferrous metals, etc. according to user requirements

Welcome new and old customers to negotiate