Reactor System

Your Current Location:Home > Product Center > Reactor System

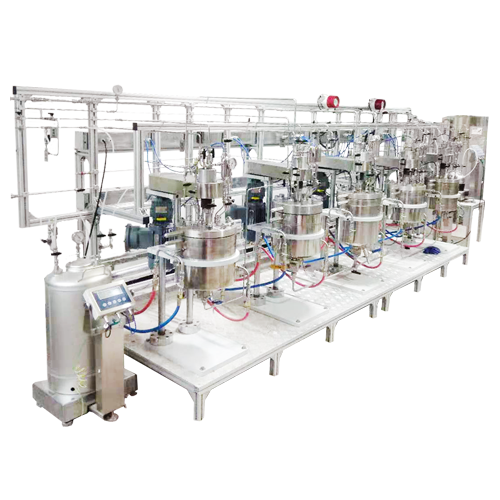

Hydrocracking reactor system

There are many types of industrial hydrocracking equipment, which are divided into one-stage method and two-stage method according to the function of the reactor.

The two-stage method includes a two-stage reactor, the first stage is used as a hydrofining section to remove nitrogen and sulfide in the feedstock oil. The second stage is the hydrocracking reaction section.

Only one or several reactors in one-stage process are used in parallel. The process flow of the one-stage fixed-bed hydrocracking unit is that the raw oil, circulating oil and hydrogen are mixed and then heated and introduced into the reactor.

The reactor is equipped with a granular catalyst, and the reaction product is separated from the gas by the high-pressure and low-pressure separators, and then the liquid product is distilled in the fractionating tower to obtain the product petroleum fraction.

The one-stage method has a relatively low cracking depth and generally uses vacuum wax oil as the raw material to produce middle distillate oil. The two-stage method has a deeper cracking depth, and generally mainly produces gasoline.

上一條:Chemical and pharmaceutical reactor with thermal oil furnace