Industrial Reactor

Your Current Location:Home > Product Center > Industrial Reactor

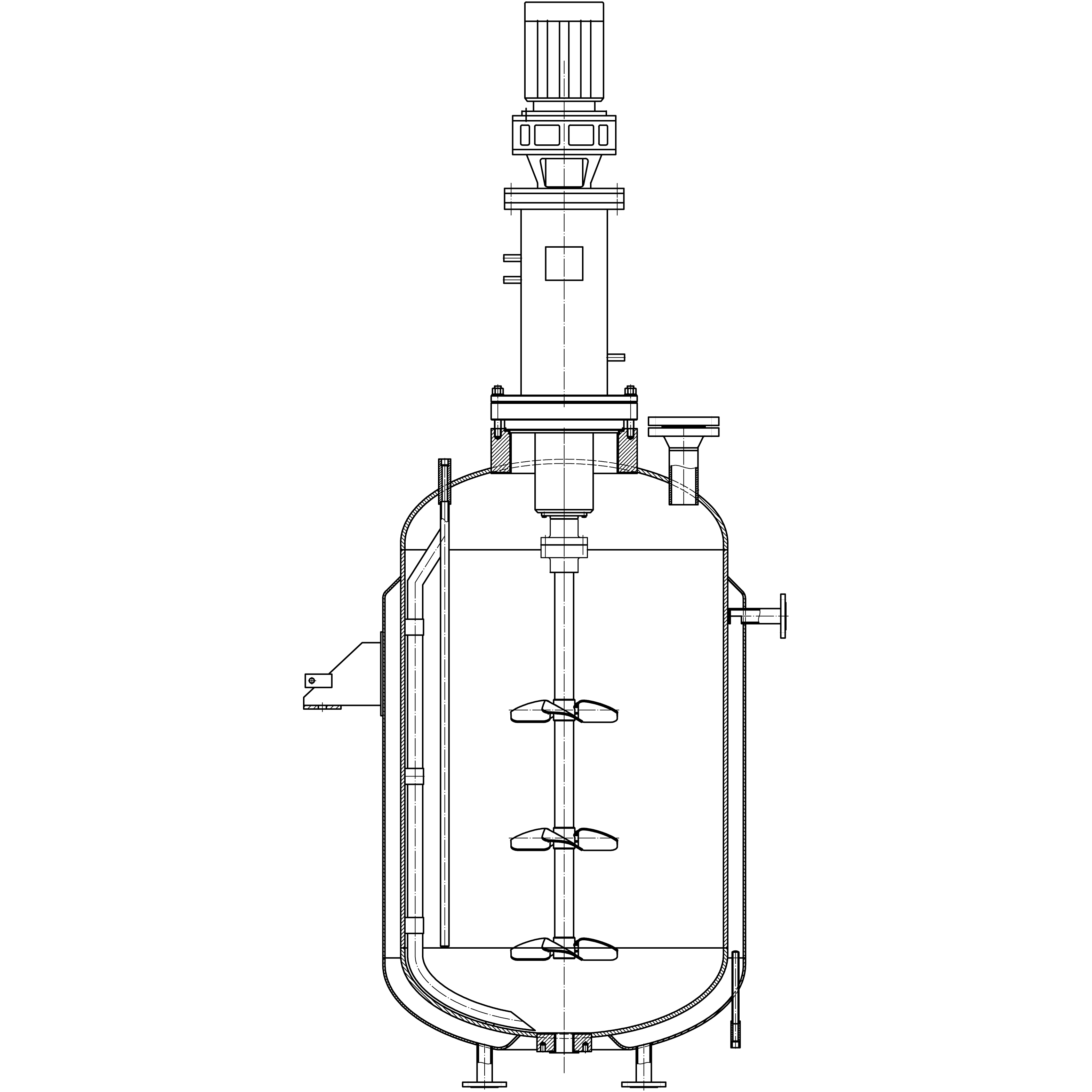

1000L industrial reactor

Through the structural design and parameter configuration of the container, the production reactor realizes the heating, cooling, evaporation, cooling and low-speed stirring and mixing functions required by the production process, so that the reaction medium can undergo physical or chemical reactions in the reactor.

The reactor is widely used in petroleum, chemical industry, rubber, pesticides, dyes, medicine, food, and is a pressure vessel used to complete vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation and other processes.

Production kettles are widely used in petrochemical, universities, research institutes, national defense technology, aerospace and military industry, medicine and food, hydrothermal synthesis, dyes, metallurgy and other units.

The contact materials of the kettle body are mainly made of stainless steel, and titanium materials (TA1, TA2), nickel materials (Ni6) and composite steel plates can be manufactured according to the requirements of different media. As well as the closed reactor body with manholes, the opening on the cover can be designed according to user requirements; heating methods include jacket steam circulation heating, jacket heat conduction oil circulation heating, jacket electric heating, and outer coil (semi-circular) Coil) heating and other forms are optional for users when ordering. For the inner surface of the kettle with polishing requirements, it can reach the level of mirror polishing, and the high-viscosity materials are processed into a tapered bottom, which is convenient for discharging and cleaning.